Test Environments

We offer tailored test environments of varying complexity for your stack module. The basic test environment uses a gas mixture of some hydrogen in nitrogen, which is available on request and brought up to operating temperature using electric heaters. SOFC stack operation can also be tested using hydrocarbons. This may involve the creation of synthetic reformate mixtures or the integration of reforming reactors into the test environment. The two primary reforming techniques (auto thermal reforming (ATR) and steam reforming (SR)) can both be used to stacks or degradation rates during the use of system-relevant fuels.

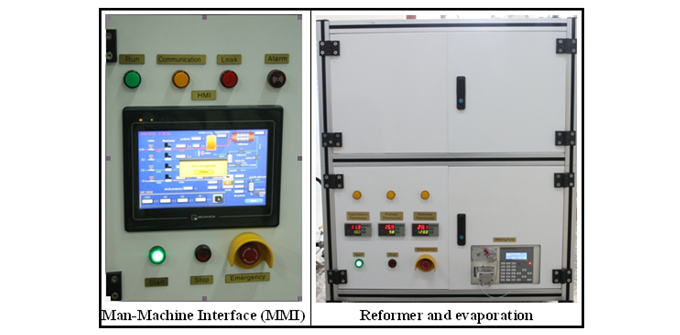

All test equipments are supplied with electric preheaters, gas and water dosing units, power circuitry and cables, the system which is equipped a 10 inch, 26 million color TFT touch screen MMI with Man-Machine Interface (MMI) and a multi-level safety system. Heat exchangers (for waste heat recovery) and waste gas burners can be integrated on request. A desulphurizer is connected in series before the stack if sulphurous gases (natural gas, biogas) are to be used.

The following test options are available:

Gas mixtures:

– Hydrogen-nitrogen mixture

– Electric gas preheater or gas-to-gas preheater

Synthetic mixture:

– Gas infeed (CO, CO2, H2, N2)

– Gas humidification

– Electric gas preheater or gas-to-gas preheater

ATR reforming:

– Air and CH4 or natural gas infeed

– ATR reformer and evaporation

– Electric gas preheater or gas-to-gas preheater

Steam reforming:

– CH4 or natural gas infeed

– Water infeed and evaporation

– Steam reformer with adjustable reforming rate

– Electric fuel gas preheater and air preheater

FEATURE:

– Available test environments on request for your stack module

– Technology based on many years of our test experience

– One-stop system supply

TECHNICAL:

(1). Performance classes: 0.5-1 kW, 1-3 kW, 2-5 kW (tailored to power performance of stack module)

(2). Operating gases: Natural gas, biogas (synthetic where required), methane, others available on request

Price:

Customized according to requirements.