Hydrogen may be fuel of 21st century provided we find large-scale and low-cost hydrogen source. Hydrogen is also preferred renewable energy storage for excessive solar and wind energy. Presently, over 90% of hydrogen is produced from natural gas,but the process is quite costly. High temperature electrolysis (HTE) uses the reversal reaction of solid oxide fuel cells (SOFCs) to produce hydrogen at a rather high efficiency – the thermo-electric efficiency of HTE can reach more than 50% if HTE is combined with renewable or nuclear energy. Therefore, the HTE is an effective way for large-scale economic hydrogen production and has become one of hot topics in energy research field. Recently, a group of researchers from the Fuel Cell and Energy Technology (FCET) Division at the Ningbo Institute of Material Technology and Engineering, Chinese Academy of Sciences (NIMTE, CAS), announced new progress in HTE process after two year research financially supported by Chinese Academy of Sciences and Ministry of Science and Technology of China.

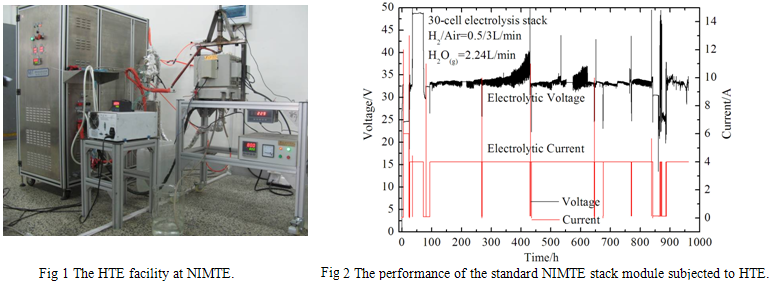

The NIMTE researchers used a standard SOFC stack module produced by NIMTE in small series for HTE research (Fig. 1). The stack contained 30 unit cells having effective areas of 70cm2. For HTE, the hydrogen electrode of the stack was fed with H2(0.5L/min)and steam(2.24L/min, 1atm, 298K) where H2 was used as protective gas medium. The stack was subjected to HTE at 800oC in the mode of solid oxide electrolyzer cell (SOEC) with a constant current of 4 A. The stack exhibited a stable performance for more than 900h without any degradation (Fig. 2). The electrolysis conversion rate was calculated 73.5% by measuring the input and output steam mass of the stack, and the hydrogen production rate was over 98.7NL/h. It is thus indicated the HTE using SOEC is effective to produce hydrogen at a high conversion efficiency and a reasonable production rate, and is of potential to scale up to a large-scale hydrogen production.